There are many things you need to keep in mind when dealing with construction debris. These include the types and disposal options for construction waste. There are also numerous regulations concerning disposal of construction debris. This article will focus on hazardous waste, recycling, the importance to seperate hazardous waste from the remainder. Once you have an understanding of these three areas you can make a decision on how to properly handle these materials.

Hazardous

The proper disposal of hazardous construction materials requires special equipment and expertise. These wastes, if not dealt with properly, can pose a danger to the environment as well as people. In addition, improper disposal can lead to fines from the state authorities. Junk King or other waste removal firms are trained to deal with hazardous construction materials. Here are some common construction wastes. These are only a small selection. Construction is fraught with hazardous waste. These are some methods to properly manage construction waste.

Most commonly, construction and demolition wastes can be transported to diversion plants by truck. The most commonly used trucks in the United States is the medium- and light-duty trucks. They are fitted with modular interoperability and can be mated together. The facility management plans will specify the materials that are allowed for disposal. Refuse haulers can reject any load containing hazardous materials. The four characteristics of hazardous waste are corrosivity, ignitability, reactivity, and toxicity. The Environment Agency and California Department of Environmental Quality (CDEQ) have to manage hazardous materials.

Recyclable

It's important that you take action to reduce the amount construction waste that ends up in the landfills. The California Green Building Standards Code requires builders to create a construction waste management plan before final inspection and permitting. The materials you can recycle include: vegetation, metals, wood, insulation, ceiling tile, drywall, plastic, glass, and cardboard. Even composites such Hardplan siding, can be recycled.

Recycling construction waste has many advantages. It helps to save energy and decrease the use of natural resource. By recycling all concrete and asphalt from US construction projects you can save an equivalent of 1 billion gallons each year. Next, by recycling your waste, you will be helping the environment by reducing toxic waste in landfills, and preventing it from entering waterways.

Off-site

The Hong Kong Civil Engineering and Development Department has two off-site CWS facilities, which handled 5.11 million tons of construction waste in February 2012. For better future results, the program should be improved. This paper reviews the CWS program in Hong Kong. It also provides concrete examples of ways to improve it. This will help construction workers reduce their waste generation and decrease hauling costs. For a more efficient waste management program, contractors should direct suppliers to reduce packaging.

Another advantage of construction waste off-site is the ability to identify the material easily and quickly. CWS that is off-site can be economically viable only if the materials are properly identified. Many contractors, subcontractors, and project specifications include protocols for jobsite waste management. The guidelines and policies that govern construction waste management may be established by building owners. Some service providers may even provide containers to store materials. It is vital to be aware of the legal requirements as well as the costs involved in construction waste disposal or recycling.

FAQ

What role does a manager play in a company?

There are many roles that a manager can play in different industries.

A manager generally manages the day to-day operations in a company.

He/she makes sure that the company meets its financial obligations, and that it produces goods or services that customers desire.

He/she ensures employees adhere to all regulations and quality standards.

He/she plans new products and services and oversees marketing campaigns.

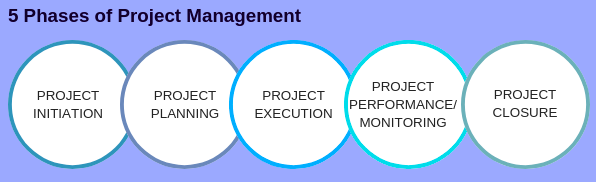

Why is project management important for companies?

Project management techniques can be used to ensure smooth project execution and meeting deadlines.

This is because most businesses rely on project work for their products and services.

Companies need to manage these projects efficiently and effectively.

Companies that do not manage their projects effectively risk losing time, money, or reputation.

What are the 3 main management styles?

The three major management styles are authoritarian (left-faire), participative and laissez -faire. Each style has strengths and flaws. Which style do you prefer? Why?

Authoritarian – The leader sets a direction and expects everyone follows it. This style works well if an organization is large and stable.

Laissez-faire is a leader who allows everyone to make their own decisions. This approach works best in small, dynamic organizations.

Participative - The leader listens to ideas and suggestions from everyone. This approach works best in small organizations where everyone feels valued.

What is Six Sigma?

Six Sigma employs statistical analysis to identify problems, measure them and analyze root causes. Six Sigma also uses experience to correct problems.

The first step is identifying the problem.

Next, data is collected and analyzed to identify trends and patterns.

Then corrective actions are taken to solve the problem.

Finally, data is reanalyzed to determine whether the problem has been eliminated.

This cycle continues until the problem is solved.

How do you define Six Sigma?

Six Sigma will most likely be familiar to people who have worked in statistics and operations research. Anybody involved in any aspect or business can benefit.

This requires a lot of dedication, so only people with great leadership skills can make the effort to implement it.

What's the difference between a program and a project?

A project is temporary, while a program lasts forever.

A project typically has a defined goal and deadline.

It is often carried out by a team of people who report back to someone else.

A program often has a set goals and objectives.

It is often done by one person.

Statistics

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

External Links

How To

What is Lean Manufacturing?

Lean Manufacturing is a method to reduce waste and increase efficiency using structured methods. These processes were created by Toyota Motor Corporation, Japan in the 1980s. The main goal was to produce products at lower costs while maintaining quality. Lean manufacturing is about eliminating redundant steps and activities from the manufacturing process. It includes five main elements: pull systems (continuous improvement), continuous improvement (just-in-time), kaizen (5S), and continuous change (continuous changes). Pull systems allow customers to get exactly what they want without having to do extra work. Continuous improvement is constantly improving upon existing processes. Just-in–time refers when components or materials are delivered immediately to their intended destination. Kaizen is continuous improvement. This can be achieved by making small, incremental changes every day. Five-S stands for sort. It is also the acronym for shine, standardize (standardize), and sustain. These five elements can be combined to achieve the best possible results.

Lean Production System

The lean production system is based on six key concepts:

-

Flow is about moving material and information as near as customers can.

-

Value stream mapping- This allows you to break down each step of a process and create a flowchart detailing the entire process.

-

Five S's - Sort, Set In Order, Shine, Standardize, and Sustain;

-

Kanban – visual signals like colored tape, stickers or other visual cues are used to keep track inventory.

-

Theory of constraints: identify bottlenecks in your process and eliminate them using lean tools, such as kanban board.

-

Just-in-time delivery - Deliver components and materials right to your point of use.

-

Continuous improvement: Make incremental improvements to the process instead of overhauling it completely.