A good project management strategy is essential to ensure that a project stays on track. There are many options for project management. Each has its own advantages and disadvantages. Some are better suited for projects requiring flexibility and others for projects that have to be completed in a timely manner.

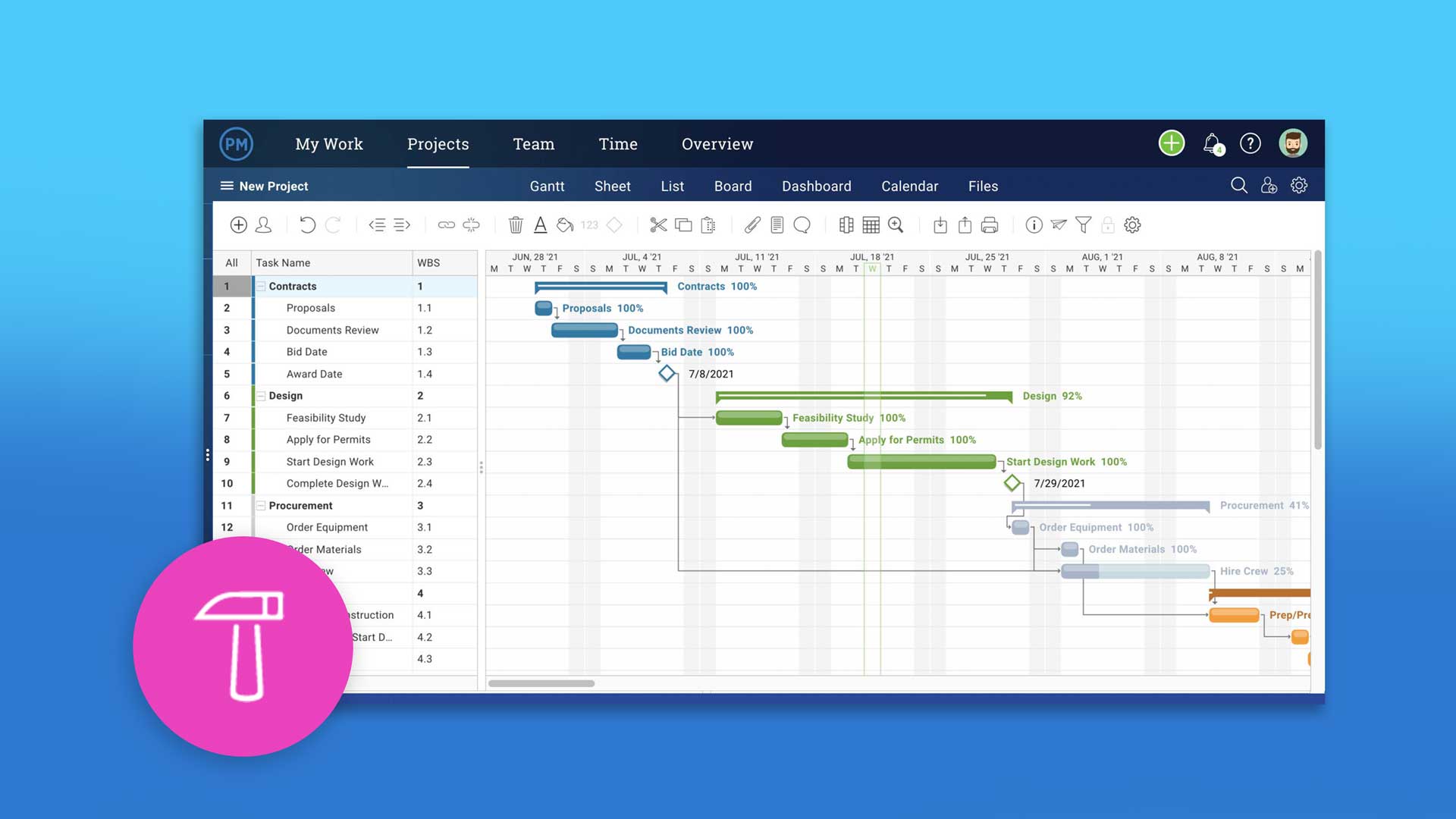

The Waterfall Technique-This is a handson approach to project managing. It is a method of breaking down projects into smaller manageable pieces. Each component can then be worked on during a sprint. The project manager provides feedback and helps overcome obstacles. The project is managed by the team until it is complete. The project manager uses a Gantt chart, a horizontal bar chart, to show the project's schedule. The activities and tasks are indicated by the bars on the chart. To mark a significant milestone, they may contain a symbol in the shape of a diamond.

The Program Evaluation and Review Technique - PERT is a project management technique that involves constant evaluation of the project. Each task is evaluated in terms of its time to complete and whether it meets the project's requirements. This technique can be very effective, and is used to measure the progress of a project and balance budget. It was used for the first time in the U.S. Navy Special Projects Office in 2005. The technique has been applied in the organization of the Winter Olympics in 1968.

Critical Chain Project Management - Critical Chain Project Management, also known as CPM, is a scheduling algorithm that was introduced by Eliyahu M. Goldratt in his 1997 book Critical Chain. This technique is useful for project managers and their teams. It allows them to evenly distribute the work and helps to keep projects on schedule.

Benefits realization Management - This method of project management emphasizes the positive aspects of a project. It also helps to reduce the risk of project failure. The project's potential benefits are evaluated and the project is constantly reviewed. You can save resources by making changes when you need them.

Agile Project Management - Agile project management is an iterative process that is designed to deliver fully-working software. It encourages collaboration with clients, and the best way to respond to any changes. This technique is perfect for highly complex projects that are in constant change. Agile Project Management's ultimate goal is to quickly and effectively respond to changes.

The Critical Path Method - This is one of the most efficient project management techniques. It identifies the tasks that require the most time, and helps the team to prioritize them based on their importance. It cuts down on the time required to complete a project and ensures that projects are completed within their timelines. This is done by creating "airbags" that can protect a project from being pushed too far ahead.

FAQ

Why is it important that companies use project management methods?

Project management techniques can be used to ensure smooth project execution and meeting deadlines.

Because most businesses depend heavily on project work to produce goods or services,

Companies must manage these projects effectively and efficiently.

Companies may lose their reputation, time and money if they do not have effective project management.

What are some common mistakes managers make when managing people?

Sometimes managers make their job harder than they need to.

They might not give enough support and delegate the right responsibilities to their staff.

In addition, many managers lack the communication skills required to motivate and lead their teams.

Some managers create unrealistic expectations for their teams.

Some managers may try to solve every problem themselves instead of delegating responsibility to others.

What is the difference between a project and a program?

A program is permanent, whereas a project is temporary.

A project typically has a defined goal and deadline.

It is often carried out by a team of people who report back to someone else.

A program is usually defined by a set or goals.

It is often done by one person.

What does Six Sigma mean?

Six Sigma uses statistical analysis for problems to be found, measured, analyzed root causes, corrected, and learned from.

The first step to solving the problem is to identify it.

The next step is to collect data and analyze it in order to identify trends or patterns.

The problem can then be fixed by taking corrective measures.

Finally, data will be reanalyzed to determine if there is an issue.

This cycle will continue until the problem is solved.

What are the five management steps?

Planning, execution, monitoring and review are the five stages of any business.

Setting goals for the future requires planning. It involves setting goals and making plans.

Execution happens when you actually do the plan. They must be followed by all parties.

Monitoring is the process of evaluating your progress toward achieving your objectives. Monitoring should include regular reviews of performance against goals and budgets.

Reviews take place at the end of each year. They allow for an assessment of whether all went well throughout the year. If not then, you can make changes to improve your performance next year.

Evaluation takes place after the annual review. It helps you identify the successes and failures. It also provides feedback on how well people performed.

What is TQM?

The industrial revolution saw the realization that prices alone were not sufficient to sustain manufacturing companies. This led to the birth of quality. They needed to improve quality and efficiency if they were going to remain competitive.

Management developed Total Quality Management to address the need for improvement. It focused on all aspects of an organisation's performance. It included continual improvement processes, employee involvement, customer satisfaction, and customer satisfaction.

How do you define Six Sigma?

Six-sigma will be well-known to anyone who has worked in operations research or statistics. But anyone can benefit from it.

This requires a lot of dedication, so only people with great leadership skills can make the effort to implement it.

Statistics

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- As of 2020, personal bankers or tellers make an average of $32,620 per year, according to the BLS. (wgu.edu)

External Links

How To

What is Lean Manufacturing?

Lean Manufacturing processes are used to reduce waste and improve efficiency through structured methods. They were created by Toyota Motor Corporation in Japan in the 1980s. The goal was to produce quality products at lower cost. Lean manufacturing focuses on eliminating unnecessary steps and activities from the production process. It consists of five basic elements: pull systems, continuous improvement, just-in-time, kaizen (continuous change), and 5S. Pull systems allow customers to get exactly what they want without having to do extra work. Continuous improvement involves constantly improving upon existing processes. Just-in–time refers when components or materials are delivered immediately to their intended destination. Kaizen stands for continuous improvement. Kaizen can be described as a process of making small improvements continuously. Five-S stands for sort. It is also the acronym for shine, standardize (standardize), and sustain. These five elements can be combined to achieve the best possible results.

Lean Production System

Six key concepts make up the lean manufacturing system.

-

Flow - focus on moving material and information as close to customers as possible;

-

Value stream mapping- This allows you to break down each step of a process and create a flowchart detailing the entire process.

-

Five S’s - Sorted, In Order. Shine. Standardize. And Sustain.

-

Kanban - visual cues such as stickers or colored tape can be used to track inventory.

-

Theory of constraints - identify bottlenecks during the process and eliminate them with lean tools like Kanban boards.

-

Just-in-time - deliver components and materials directly to the point of use;

-

Continuous improvement is making incremental improvements to your process, rather than trying to overhaul it all at once.