Price risk refers to the possibility that an asset's value will decrease over time. This can happen with any financial instrument, commodity or foreign exchange position. Hedge funds use a wider definition of price risk because of the many market factors which can cause an asset's value to fall. Hedging can be crucial in order to make a profitable investment or one that goes sour.

Investments

When investing, you should consider the price risk. When investing in financial instruments like stocks, equities or commodities, the price of a share can rise or fall over time. Investors may lose some or all of their investment due to this fluctuation. Share prices can also fluctuate because of changes in the market or general trends. This risk is often ignored, but it is essential to investing.

Commodities

There are risks associated with investing in commodities. One such risk is the volatility of price movements, which may be higher than that of other assets. Metal prices, for instance, can move by as much as 30 percent. The price risk associated commodities is more complex than that of other financial assets.

Foreign exchange

A wide variety of factors are causing extreme volatility in the currency market right now. These include Brexit and the COVID-19 flu pandemic. This volatility is an unusually large shift for the developed markets, which had been relatively stable during periods of calm and tranquility.

Financial instruments

The purpose of this book is to provide students with an understanding of price risk in financial instruments. This includes futures and options contracts. These contracts require parties that they perform a certain action. In a futures contract, for example, the buyer must purchase the underlying asset. The buyer has the option to either buy or sell a security.

Leverage

Leverage is one of the most common strategies used by both individuals and companies to invest. It can be used to kick-start a new venture or increase shareholder wealth. You can even use it as a way to purchase a home or attend college. However, it's essential to learn how to properly use it.

Hedging

A financial strategy to help companies protect themselves against price fluctuations is called "hedging price risk". It is typically done with a range of financial instruments. It can be used in almost all areas of the business. A manufacturing company would be able to hedge against foreign currency fluctuations if it sells its products internationally. However, there are costs associated with hedging.

FAQ

What is TQM and how can it help you?

The industrial revolution saw the realization that prices alone were not sufficient to sustain manufacturing companies. This led to the birth of quality. They had to improve efficiency and quality if they were to remain competitive.

In response to this need for improvement, management developed Total Quality Management (TQM), which focused on improving all aspects of an organization's performance. It included continuous improvement processes, employee involvement, and customer satisfaction.

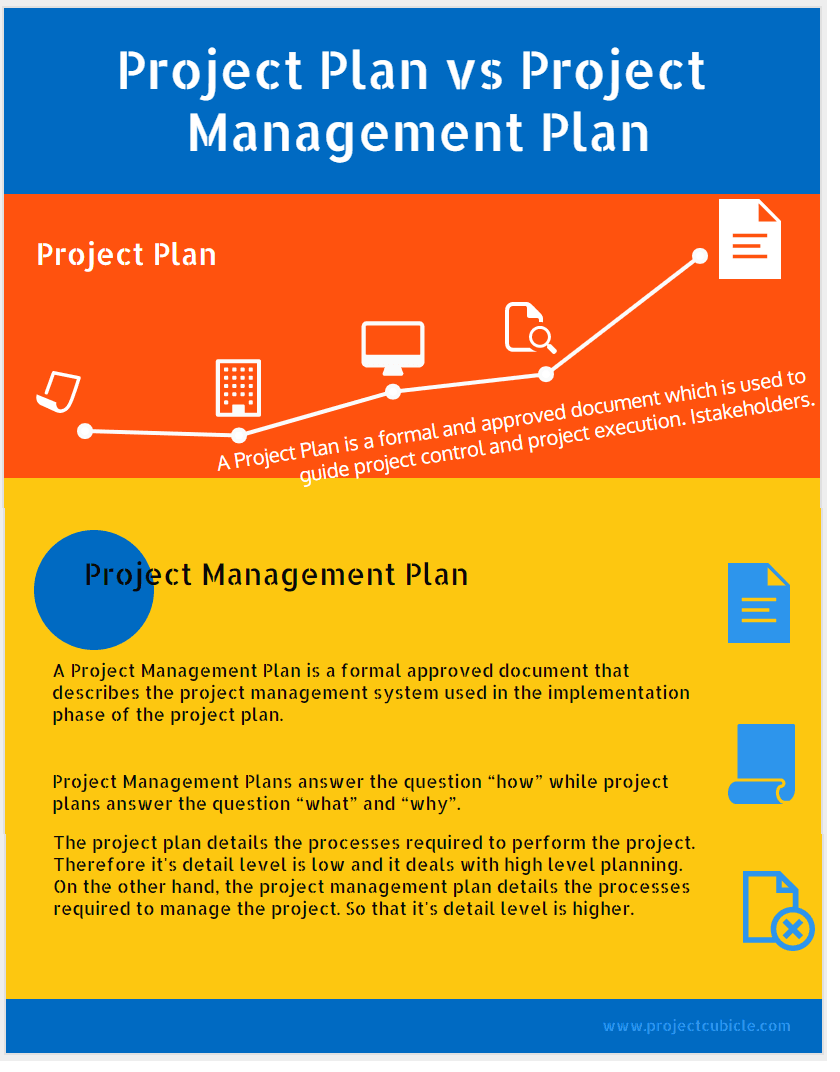

What's the difference between a program and a project?

A project is temporary, while a program lasts forever.

A project typically has a defined goal and deadline.

It is usually done by a group that reports back to another person.

A program will usually have a set number of goals and objectives.

It is often implemented by one person.

How can we create a successful company culture?

A company culture that values and respects its employees is a successful one.

It is based on three principles:

-

Everybody has something of value to share

-

People are treated fairly

-

There is mutual respect between individuals and groups

These values can be seen in the behavior of people. They will show consideration and courtesy to others.

They will be respectful of the opinions of other people.

And they will encourage others to share ideas and feelings.

In addition, the company culture encourages open communication and collaboration.

People feel free to express their views openly without fear of reprisal.

They are aware that mistakes can be accepted if they are treated honestly.

Finally, the company culture promotes honesty and integrity.

Everyone understands that the truth is always best.

Everyone understands there are rules that they must follow.

Nobody expects to be treated differently or given favors.

Statistics

- Our program is 100% engineered for your success. (online.uc.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

- As of 2020, personal bankers or tellers make an average of $32,620 per year, according to the BLS. (wgu.edu)

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

External Links

How To

How can Lean Manufacturing be done?

Lean Manufacturing is a method to reduce waste and increase efficiency using structured methods. They were developed by Toyota Motor Corporation in Japan during the 1980s. The main goal was to produce products at lower costs while maintaining quality. Lean manufacturing emphasizes removing unnecessary steps from the production process. It has five components: continuous improvement and pull systems; just-in time; continuous change; and kaizen (continuous innovation). The production of only what the customer needs without extra work is called pull systems. Continuous improvement involves constantly improving upon existing processes. Just-in-time refers to when components and materials are delivered directly to the point where they are needed. Kaizen means continuous improvement. Kaizen involves making small changes and improving continuously. Finally, 5S stands for sort, set in order, shine, standardize, and sustain. These five elements are combined to give you the best possible results.

Lean Production System

Six key concepts are the basis of lean production:

-

Flow is about moving material and information as near as customers can.

-

Value stream mapping - Break down each stage in a process into distinct tasks and create an overview of the whole process.

-

Five S’s - Sorted, In Order. Shine. Standardize. And Sustain.

-

Kanban - use visual signals such as colored tape, stickers, or other visual cues to keep track of inventory;

-

Theory of Constraints - Identify bottlenecks in the process, and eliminate them using lean tools such kanban boards.

-

Just-in-time - deliver components and materials directly to the point of use;

-

Continuous improvement - Make incremental improvements rather than overhauling the entire process.